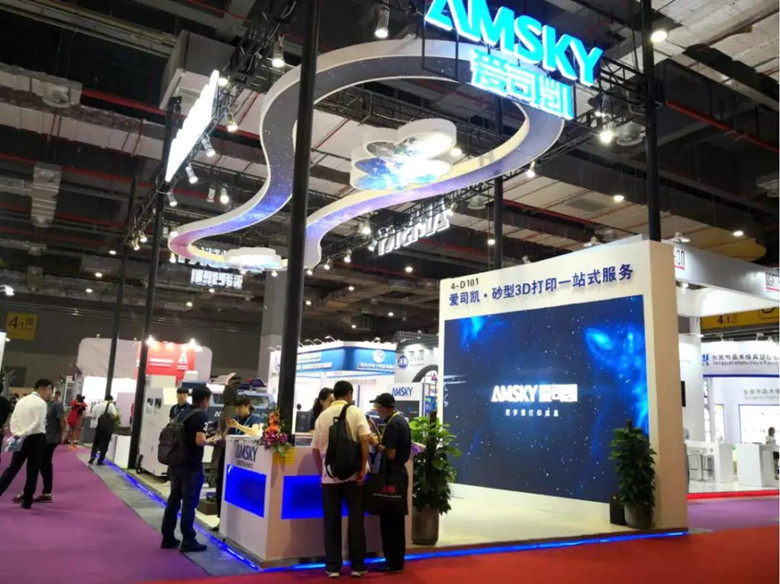

On June 11th, 2019, the annual gathering of Chinese mold manufacturing & prototyping technology and equipment-the DIE & MOULD CHINA 2019 (DMC 2019) was grandly opened at National Exhibition and Convention Center (Hongqiao, Shanghai). AMSKY, as a high-tech enterprise who committed to the R&D of industrial printing core technology and the integration of multiple technologies, actively involved himself in this event with professional team.

Themed with “Focus, Guidance and high-quality development”, DMC 2019 has striven to create a large purchasing platform for concentrated display of “LP device and automation and intelligent manufacturing technology” and “integrated molding and precision mold manufacture”.

▲AMSKY’s booth

▲ AMSKY’s booth

In this exhibition of DMC 2019, the newly added 3D additive manufacturing, laser equipment, robot automatic integration and other applications of new technologies helps a lot for molding manufacture, especially new formats such as intelligent mold design and cloud manufacturing ecosystem, etc. AMSKY launched the latest sand mold 3D printer-Sandstorm S2000; it is the 3D sand mold printer independently devolved by AMSKY one year after the appearance of Sandstorm S800 and the 3D printing solution with larger printing size and wider applications for commercial use, which is attention-attracting among the additive manufacture booths.

▲Stream of visitors

▲ Stream of visitors

In stark contrast to previous 3D device, tailor-made features, high precision, rapid build speed and cast iron frame that AMSKY Sandstorm S2000 3D printer boasts, make resolutions achieve up to 800dpi and build speed maximum 130L/h (for 0.3mm layer). Thanks to the double job boxes configuration, S2000 can print non-stop around the clock, dramatically improving the working efficiency.

▲AMSKY sand mold 3D printer-Sandstorm S2000

▲AMSK sand mold printed by Sandstorm S2000

▲AMSKY sand mold printed by Sandstorm S2000

As one of the driving forces of 3D printing technology in China, AMSKY’s investment on the R&D of 3D printing technology never abates. Sandstorm S2000, the latest sand mold 3D printer with larger printing size launched by AMSKY after Sandstorm S800, can be tailor-made as per customer and industry’s needs, such as number of print heads, resolutions, and even the size of ink drops, further bettering the printing effect.

With the further application of 3D printing technology, more surprises are around the corner. AMSKY will actively interact with the mold manufacturing industry and provide more 3D printing services to the whole mold industry and enterprises, further spurring the mold industry to have industrial upgrading.